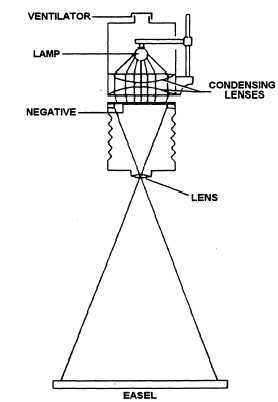

Figure 11-32.—Condenser enlarger.

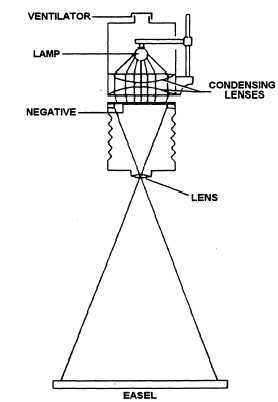

Figure 11-33.—Diffusion enlarger.

is ventilated to prevent excessive lamp heat from

damaging the negative. Some enlargers have blowers to

circulate air and cool the inside of the lamp housing.

The negative carrier used in an enlarger may be

either a dustless type or a glass sandwich type. The

dustless type of carrier is made of two metal plates with

an opening in the center large enough to hold the

negative. The negative is placed between these plates

and held in position by its edges. This type of carrier is

good for negatives 4 x 5 inches or smaller since these

negatives are stiff enough to remain flat. The glass

sandwich type of carrier is a holder where the negative

is placed between two sheets of glass. This type of

holder is used for larger negatives since they have a

tendency to sag in the center if they are not supported

by glass.

The lens used in an enlarger should have an angle

of field large enough to cover the negative being printed.

A lens with a focal length approximately equal to the

diagonal of the largest negative to be printed will

provide sufficient angle of field.

The bellows of an enlarger should be capable of

extending at least twice the lens focal length. This

amount of bellows extension is necessary for making

1:1 reproductions. Although it is possible to make

reductions to any desired size, the bellows on most

enlargers cannot be extended far enough to make

reductions smaller than 1:1. Smaller reductions can be

made by using a longer final-length lens, but a better

method is to use a reducing attachment. A reducing

attachment consists of a section of supplementary

bellows fitted with a longer focal-length lens.

MAKING ENLARGEMENT PRINTS

The darkroom arrangement for enlarging is

essentially the same as for contact printing. The

safelights should be appropriate for the type of paper

being printed. The size of the prints may require larger

trays and greater amounts of solution, but they should

be setup in the sink the same as for contact printing.

For good enlargements, good negatives, a clean

enlarger, clean printing filters, correct exposure and

development, and careful processing and finishing are

necessary. Although most any negative can be printed

by projection, there are a few characteristics that are

desirable. A good negative has normal density and

contrast. It must be sharp and free from such defects as

scratches, abrasions, dust, lint and fingerprints.

11-37