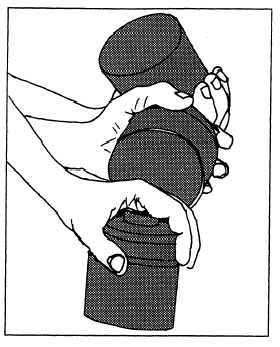

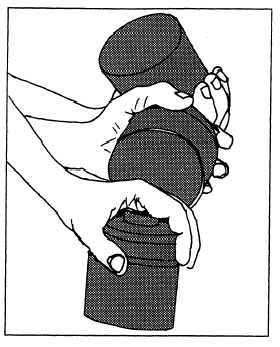

Figure 11-29.—Agitating a small developing tank.

(fig. 11-29). The initial agitation should be 30 seconds.

Place the tank in the sink on its bottom (cover up).

4. Once every minute, agitate the film for five

seconds by slowly inverting the tank end to end. After

each agitation cycle, place the tank back in the sink. If

the tank is held during the entire developing period, the

heat from your hands may heat the developer and

produce unpredictable results.

5. When only 10 seconds of developing time

remain, remove the cap from the tank cover.

Immediately start pouring the developer out of the tank

through the light trap pouring hole. Dispose of the

chemicals according to the local instructions of your

imaging facility. This step should take about 10 seconds

to complete.

6. When the developer has been emptied from the

tank, fill the tank to overflowing with stop bath. The stop

bath must be poured into the tank through the light trap

pouring hole in the tank cover. Replace the cover cap.

Agitate the film in the stop bath for about 30 seconds,

using the end-to-end method.

7. When the stop bath portion of the process is

complete, pour the stop bath through the light trap hole

in the tank cover.

8. With the tank rover still in place, pour fixer into

the tank and replace the cap. Dislodge air bubbles and

set the timer to the required fixing time. Start the timer

11-32

and agitate the film, using the same agitation as the

developer.

9. When the prescribed fixing time has elapsed,

remove the tank cover and pour the fixer from the tank

back into the bottle from which it came. Never pour the

fixer into the sink. The fixer can be reused and then

saved for silver recovery.

10. The film can be washed either in the tank or in

a roll film washer. If the tank is used, insert a hose down

through the center of the reels until it is about one-half

inch from the bottom of the tank. Adjust the water (at

the same temperature the film was processed) so a

steady overflow is created. Wash the film for about 20

minutes.

11. While the film is washing, rinse the processing

tank, tank cover and cap with clean water. Fill the tank

with water (check the temperature) and add the wetting

agent. After the film has been washed, place the film,

still on the reels, into the wetting agent solution. Replace

the tank cover and cap and agitate the film in the wetting

solution very slowly for one minute.

12. After one minute in the wetting solution,

remove the loaded film reels from the tank (Do not save

the wetting solution.)

13. To dry the film, attach the end of the film to a

clip in the drying cabinet (fig. 11-30). Let the film

unwind from the reel as you slowly lower the reel.

When the film is unwound, depress the grip clip (if

the reel has one) or remove the film from the core of the

reel. Squeegee the film and attach a second film clip to

the lower end of the film. Close the drying cabinet door

and dry the film.

CLEANING UP

After processing, the darkroom and all equipment

must be cleaned up immediately. Rinse thoroughly all

processing equipment: tanks, reels, thermometers,

funnels, and soon, in clean, warm water. Place the clean

equipment where it can dry before it is needed for the

next processing project. Always leave the darkroom

spotlessly clean and in good order.

CONTACT PRINTING

LEARNING OBJECTIVE: Recognize the

purpose of contact printing, identify the

required contact printing equipment, and

determine the procedure used in contact

printing.