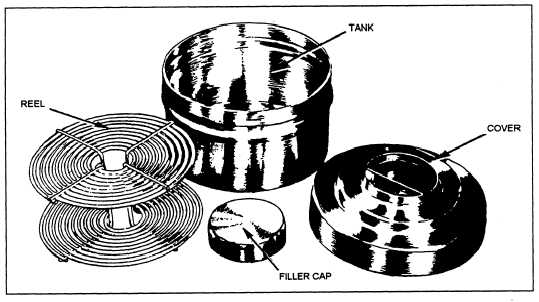

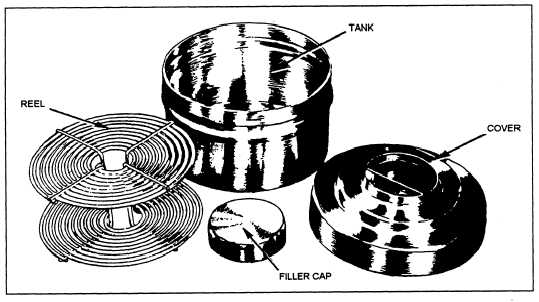

Figure 11-25.—Roll film processing tank and red.

The purpose of the fixer is to convert the silver

halides not changed to metallic silver in the developer

into a soluble form. These soluble salts diffuse out of the

emulsion and into the fixer. Navy imaging facilities use

a recovery system to reclaim silver from chemically

exhausted fixer.

Most fixer formulas include chemicals to harden the

emulsion, which is greatly softened by the alkaline

developer, and minimize scratching in later processing

and handling. There are many types of fixers and many

brands, as is the case with developers. All do their

intended job if the manufacturer’s directions are

followed.

Wash

Running water is not actually required but greatly

simplifies the removal of all the chemicals previously

used. The wash step is necessary if you desire a

permanent image without stains. Wash films and papers

with fresh running water for about five minutes.

Wetting Agent

The wetting agent, usually called Photo-Flo, is a

chemical designed to reduce the surface tension of

water, thus reducing the possibility of water spots

forming on film as it dries. It reduces the overall drying

time of your films and prints — a point to consider

especially on “rush jobs.”

DARKROOM EQUIPMENT

The equipment required to process film can be

minimal: a processing tank, graduate (measuring cup)

and thermometer. During processing, the film must be

kept in total darkness until the image is fixed. Although

there are other methods for accomplishing this, the

simplest method is to use a lighttight stainless steel tank

designed for the type and size of film being processed.

TANK DEVELOPING ROLL FILM

LEARNING OBJECTIVE: Identify the steps

involved in developing roll film in a tank.

It is more convenient to develop roll film in a small

tank than in a tray. The results are usually better, and the

possibilities of damage to the film are minimized.

Additionally, after the film is loaded in the tank you can

turn on the regular room lights and complete processing

in normal room light.

Since the film must be loaded in total darkness, you

should turn off all lights and allow your eyes to adjust

for a few minutes before opening the film container.

Examine the room for light leaks (cracks in walls,

around doors, around air conditioners or vents). If you

can see what you are doing after a few minutes, there is

too much light in the room and the condition must be

corrected before opening the film cassette.

The most common unit used to develop roll film

consists of a stainless steel, center feed, spiraled reel to

hold the film; a tank with a lighttight cover; and a filler

cap. The construction of tanks and reels differ somewhat

among the various manufacturers’ models, resulting in

differences in loading and use. However, the one you

are most likely to use is shown in figure 11-25, and the

following discussion will be based on this equipment.

11-29