237.137

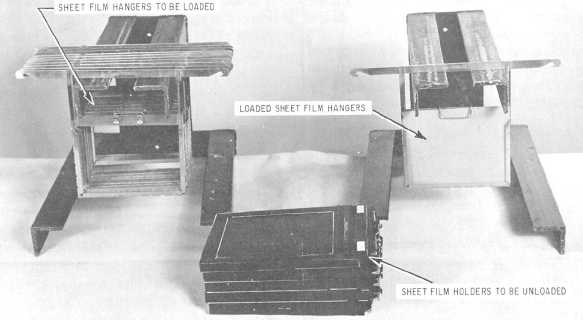

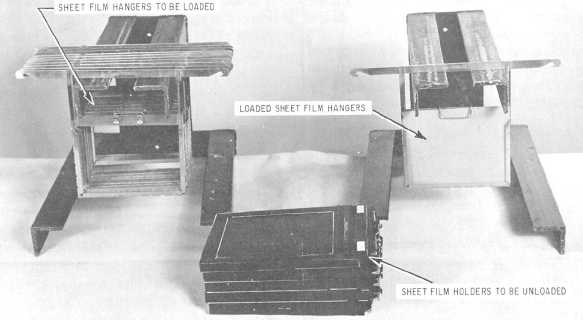

Figure 10-11.–Sheet film hangers arranged for tank processing.

8. When the timer rings, remove all the films from

the developer in the same order that they were placed in

the developer, and submerge them in the stop bath. Your

right hand should go into the stop bath with the first film

and stay there to handle each film as it is transferred from

the developer by your left hand. Use your left hand only

for transferring the film to avoid contamination of the

developer or spotting of the film. A few drops of

developer will not affect the stop bath or the fixing bath,

but a few drops of either of these solutions could rum a

developing solution.

9. After all the films have been shifted several

times in the stop bath, they should be transferred

individually to the fixing bath or hypo. Shift the films

several times in the fixing bath, agitating them

vigorously. Then safelights or the white lights may be

turned on. Continue shifting the films until they lose the

cloudy or creamy appearance. You must shift the films

several times during the second half of the fixing time,

but continuous agitation is not necessary.

10. After fixing is completed, transfer the

negatives to the wash water and continue agitation

unless a regular film washing tank or tray is used. The

negatives also may be put in regular film hangers for

washing.

11. Treat the film in a wetting agent and dry it.

TANK DEVELOPING SHEET FILM

Tank development is the recommended method for

hand processing of orthochromatic and panchromatic

sheet film. The solutions and the tanks are deep enough

to cover the films in the vertical position completely. The

films are supported individually in the tanks by the film

hangers. Films supported in this way are much less

subject to damage. The solutions last longer when used

in tanks and can process more films than when they are

used in trays.

Tank development for sheet film requires tanks to

hold the solutions, and racks, reels, or hangers to support

the films while in the solutions. The solutions used

should have good-keeping qualities, and they should be

the type that can be replenished by adding fresh solution

or replenisher, so the volume in the tanks can be

maintained at the proper working level.

The minimum number of tanks that can be used is

three: one each for developer, stop, and fixing bath.

However, when a predevelopment rinse is used, four

tanks are needed.

The tanks are arranged in the processing sink

submerged in enough water to maintain the solutions at

the prescribed processing temperature. Again the

process is arranged so you work from the left to right.

10-18