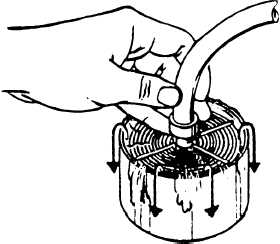

Figure 10-9.–Washing film in processing roll-film tank.

through the tank and around the film at a rapid rate. By

discharging the water from the top of the tank, you can

remove more hypo in a shorter time.

Roll film also can be washed in the roll-film tank in

which it was processed. To wash roll film in a roll-film

processing tank, simply push a small hose down into the

center of the reel and have the faucet turned on, so the

water overflows steadily from the tank (fig. 10-9).

TIMERS

Every darkroom should have a reliable timer.

Ideally, the timer should have both a minute hand and a

sweep second hand. The timer most commonly used in

the Navy is a Gray Lab timer (fig. 10-10). Not only does

this timer have a minute and sweep second hand but the

numbers and hands are fluorescent so they can be seen

in the dark A Gray Lab timer also has an alarm (buzzer)

that indicates when the time for processing is up.

PROCESSING METHODS

No matter how many rolls or sheets of film you

develop, it helps when you carry out the processing in

three distinct phases, beginning with preparation. First,

your work area must be clean, and the equipment needed

must be arranged so it is easy to locate in the dark The

second phase is processing. If you are not familiar with

darkroom work, you should complete ALL the

processing steps with dummy or practice film and water

to substitute for processing solutions under white light

and then practice a few times in the dark. The third phase

is film drying.

Figure 10-10.–Gray Lab timer.

302.285

To make the latent image visible and permanent,

you must process the film in different chemical

solutions. There are five steps in the black-and-white

processing phase. The first step is development. In this

step the film is placed in a developer that transforms the

latent image into a visible black metallic silver image.

In the second step the developing solvents are

neutralized, and development is retarded or stopped by

a rinse bath or acid stop bath, respectively. The third step

involves placing the film into a fixing bath to remove

the light sensitive, undeveloped silver halides. The

fourth step is to wash the film to remove all the

chemicals, and the last step is to dry the film. Each of

these steps is explained further in this chapter, since

there are certain controls that must be applied to each

step.

Some of the processing steps may be carried out in

white light, while others must be done under appropriate

safelight conditions or in total darkness. The steps that

must be done in darkness or under suitable safelight

conditions begin when the film package, holder, or roll

is opened and end when the film is removed from the

fixer.

As discussed earlier, there are five steps in film

processing. The steps and the lighting conditions under

which they are carried out are as follows:

1. Development-dark or appropriate safelight

2. Rinse or stop bath-dark or appropriate safelight

10-14