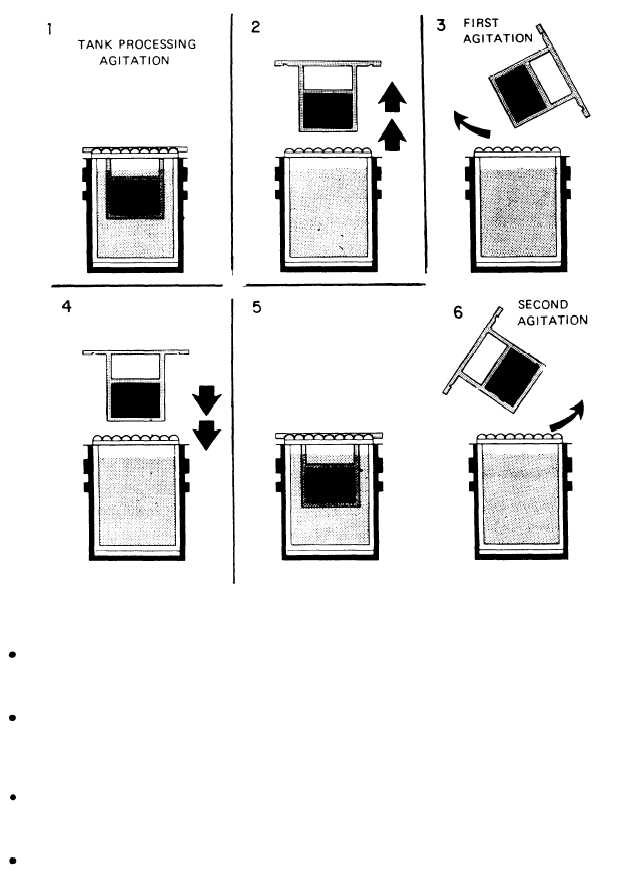

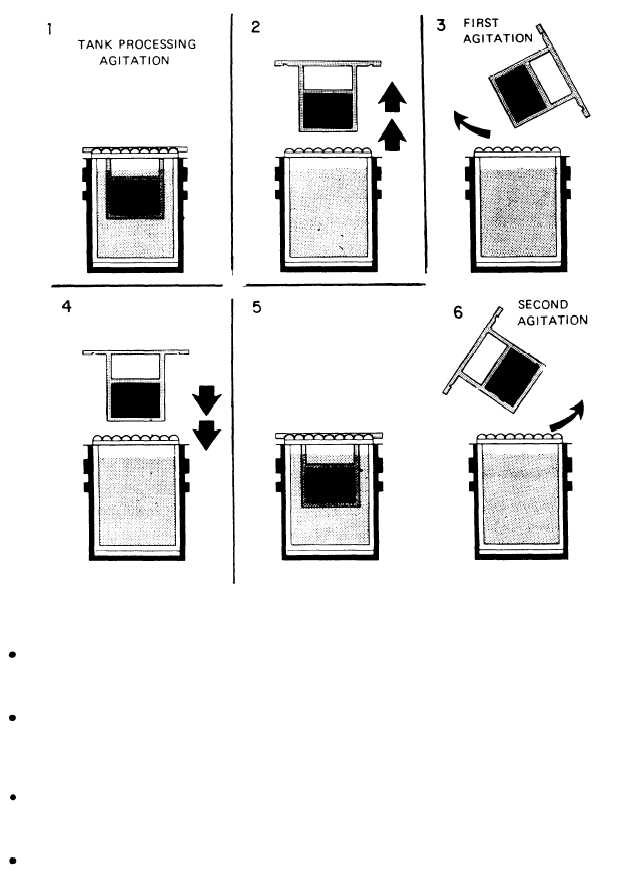

Figure 10-13.–Sheet film tank processing agitation.

The air bubbles that usually occur when dry film

is immersed in a solution can be removed without

harmful effects in the predevelopment water rinse.

When the water-softened emulsion is placed in

the developer, the action of the solution begins

uniformly over the entire emulsion. Thus uneven or

streaky development is avoided.

The predevelopment water rinse removes the

antihalation backing dye that interferes with the action

of some developers.

The predevelopment water rinse brings the

temperature of the film and the hangers to the processing

temperature. Maintaining constant temperatures in all of

the processing solutions is very important.

The predevelopment water rinse is given by

immersing the loaded hangers in a tank of water and

agitating them for about 2 minutes. The temperature of

the water should be the same as that of the other

processing solutions. The loaded hangers are then lifted

out of the water, drained by one comer, and processed

in the usual manner.

Immerse the hangers in the developer slowly and

smoothly to avoid splashing or the formation of air bells.

Air bubbles usually result when films are immersed

rapidly, especially when a predevelopment water rinse

was not used. All the hangers should be immersed

simultaneously to assure uniform agitation and

development.

Strike the hangers sharply against the sides of the

tank several times to dislodge any air bubbles that may

10-20