303.41

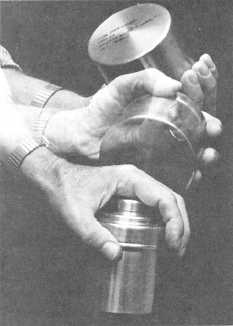

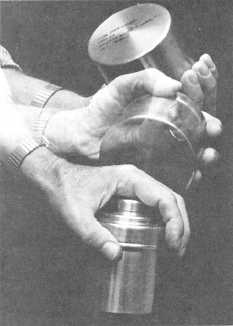

Figure 10-19.–Agitation of a small tank.

fixer into the sink. The fixer can be reused and then later

saved for silver recovery.

11. The film can be washed either in the tank or in

a roll-film washer. When the tank is used, insert a hose

down through the center of the reels until it is about 1/2

inch from the bottom of the tank. Adjust the water (at

the same temperature the film was processed) so a

steady overflow is created. Wash the film for about 20

minutes. When you use a rapid roll-film washer, again,

adjust the water temperature and place the reels

containing the processed film into the washer. Adjust the

rate of water flow until the reels start to turn. When the

reels start to turn, adjust the rate of water flow until the

reels stop turning. Set the timer and wash the film for

about 5 minutes.

12. While the film is washing, rinse the processing

tank, tank cover, and cap with clean water. Fill the tank

with water (check the temperature) and add the wetting

agent. After the film has been washed, place the film,

still on the reels, into the wetting agent solution. Replace

the tank cover and cap and agitate the film in the wetting

solution very S-L-O-W-L-Y for 1 minute.

13. After 1 minute in the wetting solution, remove

the loaded film reels from the tank. (Do not save the

wetting solution.)

14. To dry the film, attach the end of the film to a

film clip in the drying cabinet. Let the film unwind from

the reel as you slowly lower the reel.

When the film is unwound, depress the grip clip (if

the reel has one) or remove the film from the core of the

reel. Squeegee the film and attach a second film clip to

the lower end of the film. Close the drying cabinet door

and dry the film.

Photographer’s Data Sheets

Sometimes a photographer's data sheet will

accompany film that enters your imaging facility to be

processed. The photographer's data sheet will provide

you with information on how the film was shot, lighting

conditions, and specific processing instructions. When

a photographer's data sheet accompanies the film or job

order, you should process the materials specified by the

form.

Cleaning Up

10-25

After processing, the darkroom and all equipment

must be cleaned up immediately. Rinse thoroughly all

processing equipment: tanks, reels, hangers,

thermometers, funnels, and so forth, in clean, warm

water. Place the clean equipment where it can dry before

it is needed for the next processing run. Always keep the

processing room shipshape.

REVERSAL PROCESSING

Normal processing of black-and-white film

produces a negative; from this negative, a positive is

made. However, by using the reversal process, you can

produce a positive image directly on the

black-and-white film.

In the reversal process, a negative image is first

obtained by developing the original latent image in a

developer that contains a silver halide solvent. This

developer dissolves some of the excess silver halides.

After leaving the developer, the negative image is

dissolved away in a bleach bath. The silver halides

remaining are chemically “exposed” (fogged) and

developed by a second developer that provides the

positive image.

Not all black-and-white films reverse well. Films

that reverse well are Kodak Direct Positive

Panchromatic Film 5246 (35mm), T-max 100 Direct

Positive Film, and Kodak Technical Pan Films (35mm).

Instructions for reversal processing of these films can

be found in the Photo-Lab-Index.