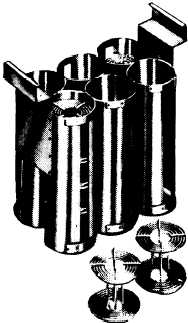

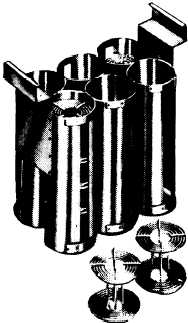

Figure 10-14.–Reel processing rack.

with a film clip. Dry the hangers, after washing them in

hot water, without film in them.

With suitable racks designed to hold reels, roll film

can also be processed in tanks (fig. 10-14).

TANK DEVELOPING ROLL FILM

have formed. Start the timer and agitate the film for 1

minute. After the first minute of development, agitate

for 5 seconds at l-minute intervals.

The most convenient and reliable way to hand

process roll film is in a small roll-film tank. The

construction of tanks and reels differ somewhat among

The processing tank usually has enough space for

several additional hangers. However, this space is

needed for proper agitation of the film hangers.

Agitation should be accomplished by lifting the hangers

out of the tank draining them momentarily from a

the various manufacturers’ models, resulting in

10-21

differences in loading and use. Generally, the basic unit

used in Navy imaging facilities consists of a stainless

different comer each time, and replacing them in the

solution (fig. 10-13). Hangers should not be agitated too

vigorously from side to side. This forces the developer

through the holes in the hangers at high speed, causing

developing trails near the holes. The objective is to

assure an even flow of fresh solution over the surfaces

of the films regularly according to a fixed schedule.

About 10 seconds before completion of the

developing time, lift each of the hangers out of the

solution, let them drain for 10 seconds, then lower them

into the stop bath. Agitate them several times in the stop

bath, drain them, lower them into the fixing bath, and

agitate them constantly for 2 or 3 minutes.

The fixing and the washing requirements are the

same as described previously in this chapter. When

washing is complete, place the film hangers and film

into a wetting agent; then remove each sheet from its

hanger and hang it up by one corner to dry.

When the film is dried in the hangers, there is a

number of drying marks along the edges of the film, thus

reducing the actual usable size of the negative image. It

is better to suspend each film individually from a line

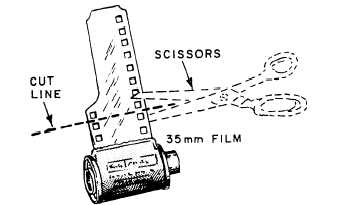

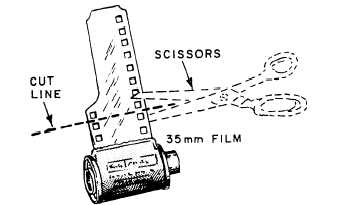

rewound, you do not have to open the cassette to remove

the film. The leader or loading tab on 35mm film can be

cut off square while in the light to ease loading of the

spiral reel (fig. 10-15).

Figure 10-15.–Cutting leader tab film 35mm film.

steel, center feed, spiraled reel to hold the film; a tank

with a lighttight cover; and a filler cap. Each reel is

constructed for a specific size roll of film; for example,

35mm, 120, and 220. The tank top permits pouring the

chemicals in and out of the tank under white light

conditions. The tanks come in sizes to hold from one

35mm reel to as many as eight 35mm reels or five 120

reels. Small roll-film tanks of all metal construction

(tanks, lids, caps) should be numbered or marked in such

a way that prevents mixing different tanks, lids, and

caps.

The proper loading of a film reel in total darkness

can be the most important steps and challenges in

processing roll film.

When processing roll film with a paper backing, the

paper tape sealing the exposed roll should not be broken

until the lights have been turned out. Also, for 35mm

film, the cassette should not be opened until the lights

have been turned out. If a short length of film is left

protruding from the 35mm cassette when the film is