Any monitoring system for the photographic

process requires that a reference or standard be

established. By systematically comparing daily

production to the reference, you can detect, identify,

and correct errors in procedure.

Any photographic quality assurance system should

be built around the science of sensitometry. In its

broadest terms, sensitometry, as applied to the whole

photographic process, includes methods of

measurement, process control, and data analysis. It

deals with all areas of the photographic process, from

exposing film to viewing the final image.

SENSITOMETRY

In the Photography (Basic), NAVEDTRA 12700,

training manual, the quality of the photographic

product was judged only from its visual aspects. As

a further step, you should know of other controlled

working methods and techniques that ensure

photographic quality. This area of control, or

sensitometry, is one method of using certain

photographic theories to improve photographs while

saving time, effort, and materials.

With sensitometry, variations from the standard

and recommended corrections are expressed in

numbers and not in terms of personal opinion.

Sensitometry provides a permanent record of the

process and indicates whether the system was in

control when a given film or paper was processed

The accumulated data is helpful for determining the

cause of poor quality and the exact amount of

deviation from the standard.

The first requirement in photographic quality

assurance is establishing a standard for good

processing and the range or limit that quality should

not exceed. The standard is based on developing the

same film or paper that is given a known exposure

and comparing the resulting densities.

Black-and-white processing is discussed first in the

following paragraphs.

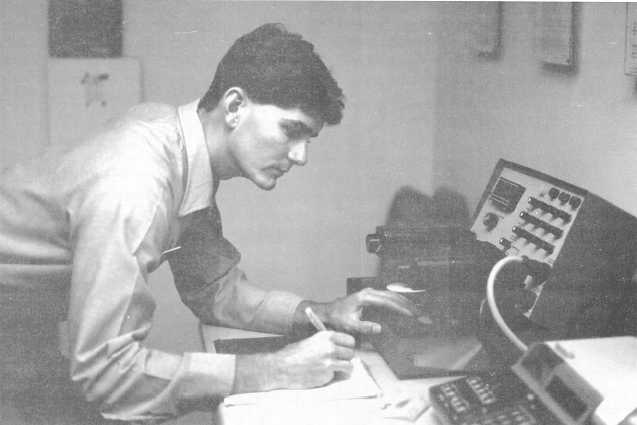

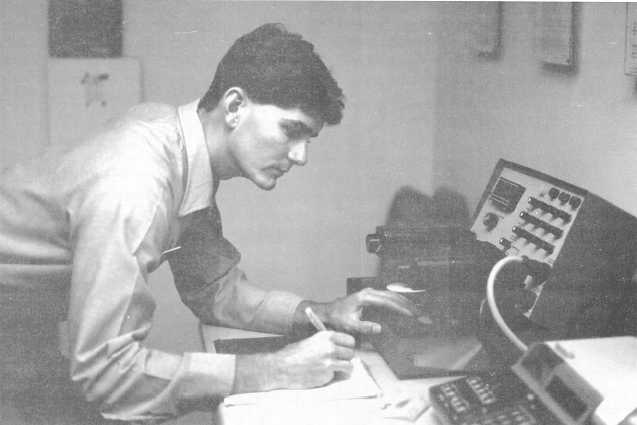

Figure 2-1.—A Photographer’s Mate uses a densitometer to read a control strip.

2-2