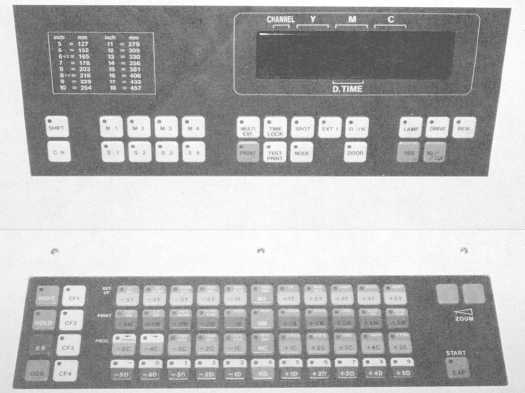

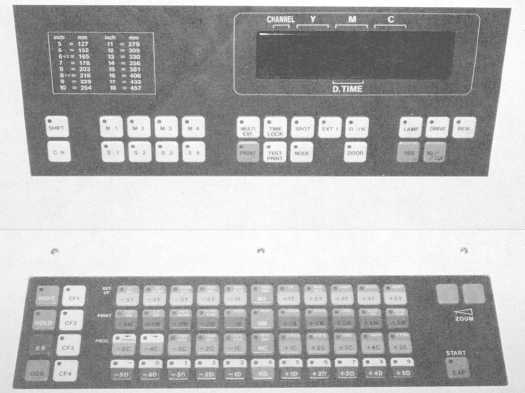

Figure 12-9.–Keyboard of a Noritsu Model 1001 print processor.

Minilabs have a microprocessor that stores

information put in by a programmer. The information is

retrieved through channels. The channels are

programmed for different film manufacturers, ISOs,

negative sizes, print sizes, and paper combinations. The

various information combinations that are stored in

these channels are used to print production negatives;

for example, a 35mm Kodacolor negative to a 4x5 print

is printed on one channel, and 35mm Fujicolor negative

to a 5x7 print is printed on another. By programming

different negative and print combinations into separate

channels, you are able to produce production prints

which have good density and color balance from the

automatic printer. You can also fine-tune the density and

color by using the keyboard.

Color correcting on a minilab is less complicated

than on an enlarger. The keyboard of the printer contains

yellow, cyan, magenta, and density keys. These keys

range in value so you can make minor or major

adjustments. When the density of the print is off, density

can be either added or subtracted. When a production

print has too much cyan, yellow, or magenta, these

colors are subtracted. When the print has too much red,

green, or blue, the complement of these colors is added.

302.266

After the prints are exposed, the paper is fed

automatically into the processing section of the minilab.

The processing section contains chemical tanks and a

dryer section. Each tank has a roller assembly rack that

transports the print through the processor. Minilabs

require no plumbing or drains because they use a

washless process, such as KodakRA-4 chemistry. When

Kodak RA-4 chemistry is used, the total processing time

is completed in about 4 1/2 minutes.

The setting up and programming of automated

printers can be complicated. You are expected to be a

printer operator only. Programming the channels,

density, and color balance of automated printers should

be left to the more experienced imaging facility

personnel.

While automated printers are very useful in

controlling a high influx of production, there are

disadvantages in their use. Not all imaging facilities

have the space required to support automated printers.

Cropping is very restricted, and dodging and burning

cannot be performed. Like all machines, automated

printers require maintenance. They also must be

programmed accurately to function the way they are

designed. Without the support and expertise of

knowledgeable personnel, normal projection printing

may be preferred.

12-17