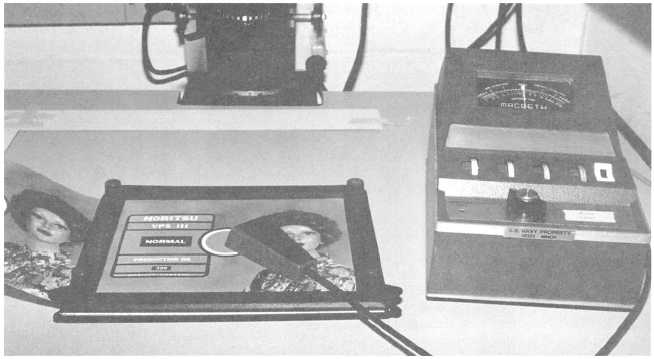

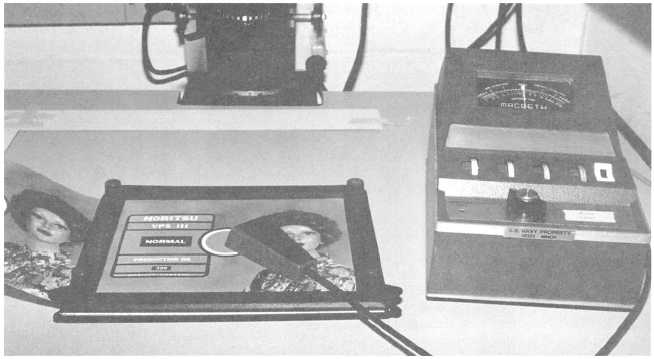

Figure 12-5.–On-easel color analyzer.

302.261

negative to be printed is then read on the densitometer

and these densities are subtracted from the total density

values of the standard negative (negative reference

patch and enlarger filter pack). This method of

evaluation does not indicate directly the required

exposure for the production print, but the production

print exposure can be estimated closely by using the

standard negative exposure and compensating for any

changes to the filter pack. An example on how this

off-easel evaluation system operates is as follows:

Gray patch of standard

negative

= 47C 51M 50Y

Established filter pack for

standard negative

= 0C 47M 34Y

Sum:

47C

98M

84Y

Subtract gray patch of

production negative

–44C 63M 49Y

Difference:

03R

35G

35Y

To illuminate neutral density

– 03 03 03

Production negative filter pack

0C

32M

33Y

A reflection densitometer also can be very useful in

color print evaluation. A reflection densitometer can be

used to match an earlier printed print with the color print

you are currently printing. To use a reflection

densitometer as an aid in color printing, you must

compare or read a reference area on your test print. This

is particularly useful when you are making a color print

with neutral areas. As you know, black, gray, and white

have approximately equal portions of red, green, and

blue. By taking a reflection densitometer reading

directly from one of these neutral areas (such as a gray

card, the side of a ship, or part of a gray aircraft), you

can determine what color and the amount of that color

in excess. To change your filter pack for print

corrections, you must take one half of the density value

as read from the densitometer and either add or subtract

that value from your filter pack; for example, you take

a reflection densitometer reading from a gray patch on

your color test print. Your density readings are 50R,

50G, and 70B. The densitometer indicates that your test

print is high by 20B (too much yellow dye). To adjust

the filter pack, you should add CC10Y to your filter pack

for subtractive printing or add CC10B on an additive

printer.

Another off-easel color evaluation system is a color

video analyzer. This system scans the color negative and

is viewed directly on a color monitor. The image on the

monitor can be manipulated until the proper color

balance, density, and image size are achieved. The

12-12