The principles of making color positive prints from

color transparencies are the same whether coupler

development or dye destruction materials are used.

Colored filters are used to alter the printing light to

obtain proper color balance, much the same as is done

in printing color negatives.

You must keep in mind, however, that you are

working with color positive materials, and not negative

materials. The borders of these positive materials are

black when unexposed. Dust particles and scratches also

appear black. To make a test print lighter, you must

increase the exposure. Dodging darkens selective areas

of a print, and burning in lightens selective areas of a

print. Color corrections are performed the same as the

visual appearance requires.

AUTOMATED PRINTERS

Many Navy imaging facilities have automated

printers that print photographic negatives. Most can be

used to print both black and white and color. When

high-volume production is routine in an imaging

facility, automated printers are an invaluable piece of

equipment.

There are many types of automated printers

throughout the fleet. Some types hold long rolls of

photographic paper that must be taken out and processed

through a processor. Other more sophisticated types

analyze, expose, cut, process, and dry the paper auto-

matically.

ROLL PAPER PRINTERS

The roll paper printer is very popular on larger ships

and shore stations that produce a large volume of color

prints. The advantages of roll paper printers are they are

operated under normal room lighting conditions, and

they are very useful when a large number of the same

size prints are needed from a single negative. When

these printers are used, the correct density and color is

accomplished by making test prints. Once the

corrections and number of prints required are keyed into

the printer, the printer makes each exposure and

advances the paper automatically. When the printing is

completed, the exposed roll of paper is removed and

processed. After processing, the prints are then cut from

the roll with a paper cutter.

Roll paper printers have built-in analyzers. These

analyzers are calibrated using standard negatives. When

a production negative is printed, the machine refers to

the memory and produces a print using the information

stored from the standard negative. Generally, that

produces a print that closely represents the original

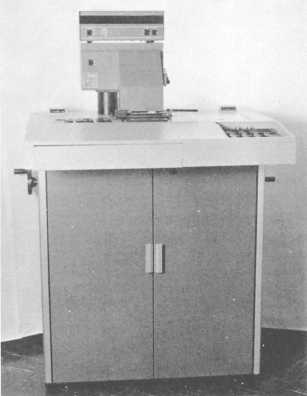

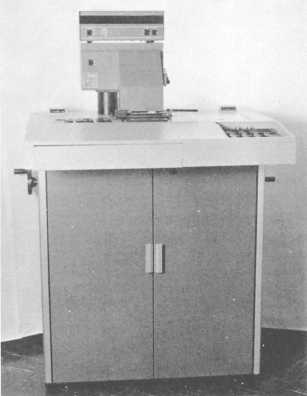

PH1 Slaughenhaupt

302.263

Figure 12-7A.–Front view of Pako BC 24 roll paper printer.

scene; however, test prints are still made to produce the

highest quality prints possible. The most popular roll

paper printer used in Navy imaging facilities is the Pako

BC 24 (fig. 12-7A and fig. 12-7B).

MINILAB SYSTEMS

Minilab systems (fig. 12-8) have become very

popular in Navy imaging shore facilities and aircraft

carriers. These types of printers are fast and can be used

to rush production. In these systems, the printer and

processor are combined into one unit. The printer cuts

the paper to size, exposes it, and automatically feeds it

through the processor. Minilabs (as they are called) are

used in all of the “One Hour” photo-finishing shops that

you see today.

The operation of a minilab is very easy once you

become familiar with the system. Minilabs can be

operated under normal room lighting conditions. The

printer is controlled by a keyboard (fig. 12-9). Some

systems have zoom enlarging lenses to alter the image

size. The negative can be aligned and composed by

adjusting the negative carrier. These adjustments to the

image size and cropping can be seen on a viewing

screen.

12-15