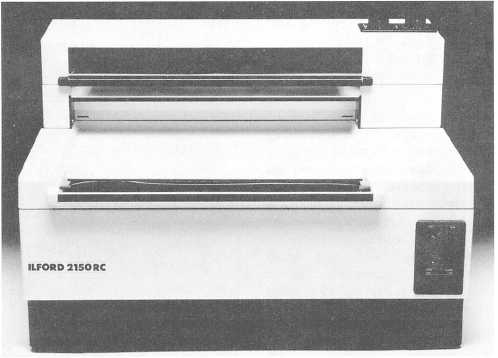

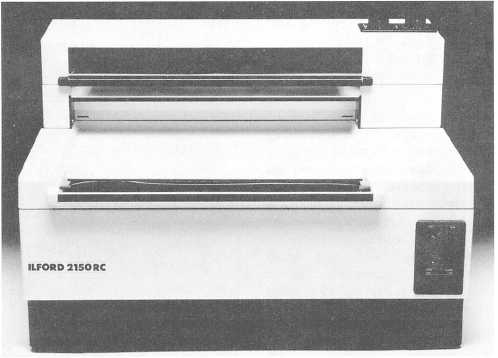

Courtesy of Ilford Photo

302.307X

Figure 11-6.–Ilford 2150 black-and-white paper processor.

temperature. The prints should be dry in 10 to 15

minutes.

In the Navy today, most imaging facilities process

prints through automatic processors (fig. 11-6). It is

important for you to know how to process

black-and-white prints in trays, because not all of the

small facilities have automatic machines. Like all

machines, automatic processors breakdown and require

maintenance periodically.

When processing photographic prints through an

automatic processor, you feed the unprocessed print into

the machine; and within seconds, it exits the processor

washed and dried. Your hands never get wet, and you

can process a large number of prints rapidly. The two

most common black-and-white print processors used in

the Navy are manufactured by Ilford and Kodak.

When contact printing an entire roll of negatives

that are not consistent in exposure, it is necessary for

you to make more than one proof sheet from the same

set of negatives. Each sheet of paper should be exposed

to print some of the negatives correctly on that roll. The

result is a composite proof sheet where all the frames

are readable. After all, a proof sheet is a tool to select

the best frames for enlargement and delivery to the

requester. The proof sheets can be stapled together for

filing. This is why, as a photographer, you should strive

to expose each and every photograph correctly. Amateur

snapshooters can shoot film with wildly varying

exposures; professional photographers cannot. A good

print shows detail in both the highlights and the

shadows.

Cleanliness is essential to produce good prints

consistently. Keep a supply of clean towels handy, and

wash and dry your hands before handling paper and

negatives. Clean, dry fingers should touch only the

extreme edges of the emulsion side of these papers.

When developer is on your hands, dark fingerprints

show on the print. Fixer produces white fingerprints.

These fingerprints develop and show clearly on the

finished prints. You should use two print tongs–one for

the developer and one for the stop and fixing baths.

It is not economical to use minimum quantities of

developer. Small quantities oxidize (turn brown) very

quickly. Oxidized solutions cannot produce clean,

brilliant, pleasing photographs.

PROJECTION PRINTING

Projection printing is the process of making positive

prints by projecting the negative image onto

photosensitive paper. The projected image may be

11-8