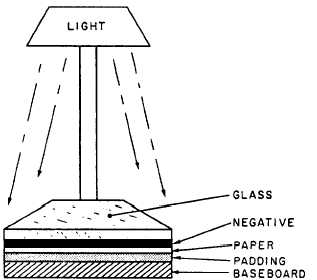

Figure 11-2.–Contact printing arrangement.

source, and some sort of padding. For large volume and

fine printing control, a specially designed and

constructed contact printer is used

Glass and Pad

For you to make contact proof sheets and an

occasional contact print job, only a glass and a

supporting pad are necessary. “Contact printers,”

consisting of a sheet of glass hinged to a metal frame

and a pad assembly, are generally known as proof

printers (fig. 11-1). When such a device is not available

or is not large enough for the negatives to be contact

printed, a piece of 1/4-inch plate glass and soft padding

(such as a rubber typewriter pad) can be used.

Quarter-inch plate glass is heavy enough to keep the

negatives and paper flat and in contact during exposure.

The glass must be free of flaws, scratches, bubbles, and

dirt. For color contact printing, the glass should be water

white or crystal grade; otherwise, filtration is required

to overcome the color tint of the glass. The edges of the

glass should be beveled and the corners slightly rounded

or taped. This is a safety measure to prevent cuts when

the glass is being handled.

The pad should be at least as large as the glass. The

pad provides a cushioned surface to press the paper and

negative together under pressure from the glass.

To use either the proof printer or the glass and pad

to make contact prints, you should place the printing

paper emulsion side up on the pad material. The

negatives are then placed emulsion side down on the

paper and the glass is positioned on top. Then turn on

303.47

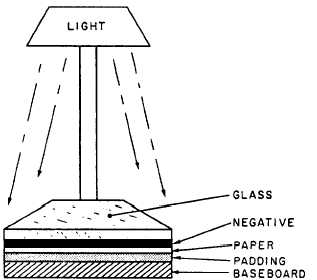

Figure 11-3.–Using an enlarger as a light source for contact

printing.

the exposing light (fig. 11-2). This, of course, is done in

the darkroom under suitable safelight illumination.

Adequate pressure must be kept on the negative and

print paper so their entire surfaces are in contact during

the exposure. Any separation between the negative and

the paper results in an unsharp point in the image.

The light source may be any controlled lamp for

printing with a proof printer or glass and pad. An

overhanging light bulb or a safelight, with the filter

removed, connected to a timer is a convenient

arrangement. In most Navy imaging facility print

rooms, an enlarger is used as the light source (fig. 11-3).

Contact Printer

For large volume contact printing, a contact printer

is more convenient. A contact printer is basically a box

with exposing lights, safelights, and viewing lights

inside with a glass top. It has a hinged pressure cover to

hold the negative and paper in contact during exposure.

Switches on the printer control the lights in the printer

or the printer may have a built-in timer. Also, the contact

printer may be connected to an external timer.

Contact printers are all built around the same basic

idea. However, consult the manufacturer’s instructions

11-3