Chemical Analysis

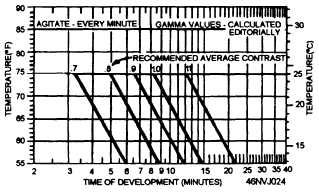

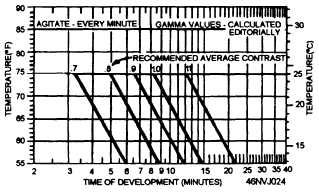

Figure 2-11.–Time-gamma temperature chart.

line until it intersects the bold line labeled .9 (0.90

gamma). From this point, drop straight down to the

time of development line and read 7.5. It takes 7 1/2

minutes of developing time at the recommended

agitation.

Much of the chemical analysis performed is

accomplished by using common sense. Practices,

such as cleanliness, accuracy, and proper preparation

of solutions, should be observed at all times.

Contamination can ruin a developer which, in turn,

could ruin your images. Things, such as dirt and dust,

in the solution can cause artifacts on the film.

Before equipment is used for mixing and

measuring chemicals, you should clean it thoroughly.

Use a good-quality medium-strength detergent to wash

glassware and other vessels. Be sure that all washed

items are rinsed well with clean tap water. Keep the

entire area clean to prevent contamination and ensure

accuracy.

Some of the more common chemical analysis

methods you will use are as follows:

Determining pH

CHEMICAL QUALITY ASSURANCE

Measuring specific gravity

The equipment and methods used presently for

mixing photographic solutions are the result of

changes that have taken place over many years.

These improvements are made to keep pace with

improved sensitized materials, processing equipment,

and environmental regulations.

Substandard solutions make it impossible to

operate a processing system within controlled limits.

The preparation and use of photographic solutions

must be a systematic procedure based on accurate

measurement and standardized methods. High-quality

standards can be achieved only when the conditions of

exposure, chemistry, and processing are all within

operating tolerances. Then results are predictable.

In certain critical processing areas, chemical

analysis is used to check solutions before and during

use. This helps us to keep chemicals up to standard.

Analysis of the components of processing solutions is

often used as a basis for discarding solutions or

adjusting their composition for future use. These

procedures are used to determine proper replenishment

rates to promote the efficient use of chemicals.

Quality assurance procedures are implemented, so

solutions are mixed, used, and discarded properly.

Sensitometric testing

Although there are several reasons for certifying

photographic solutions, the principal objective is to get

desirable, predictable, and consistent results.

Control of a photographic process requires that the

chemical activity of the solutions be maintained.

Chemical analysis procedures used to indicate

chemical activity are valuable only when the samples

analyzed are representative of the processing solutions.

The analysis of a sample taken improperly may do

more harm than good in controlling the process.

Processing solutions may be clouded or contain

floating particles, dispersed oil droplets, or a

precipitate. Even a clear solution may have different

concentration levels in various parts of a processing

tank; for instance, the chemical composition at the

point where the film enters may not be the same as in

other parts of the tank. To compensate for this, you

must use a prescribed procedure, so all the samples

are taken from the same location, such as from a point

near the tank overflow. These samples should be

representative of the solution at an established

2-21