When you are using a new developing solution,

time-gamma or time-contrast index charts (as

appropriate) must be developed for the variety of

films to be processed in it. Given time, temperature,

and agitation for each particular film in the developer,

you will be able to see the results on these time

charts.

After the developer solution has been proven, you

should process a sensitometric strip with each process-

ing run. Each sensitometric strip should be read with

a densitometer and plotted on the appropriate pro-

cess-monitoring chart. As a minimum, you should

process and plot a control strip after start-up and

before shut down or at the beginning and end of each

work shift. Once the densities are recorded and

plotted, an accurate graphic representation of the

activity of the process is provided.

QUALITY ASSURANCE

CONTROL CHARTS

In photographic processing, control charts are used

to monitor the status of specific solutions and the

physical process. A list of numbers can be studied

carefully to see whether they are out of line; however,

when the numbers are plotted on a chart, you can see

instantly whether there is data out of order.

Photographic quality assurance control charts can

be prepared for gamma or contrast index, minimum

and maximum density (D-min and D-max), average

density ( ), gross fog, temperature, pH, specific

gravity, or any other variable that may be required by

your quality assurance program. To be useful in your

quality assurance program, you must collect and

record data relative to these and other specific

factors. From the recorded data, you can calculate the

mean or average, and determine the upper and lower

limits.

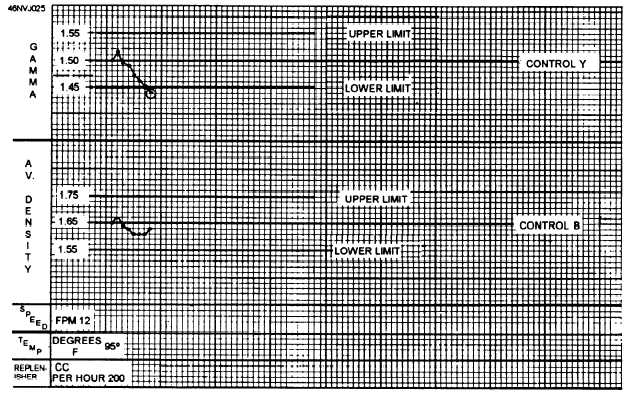

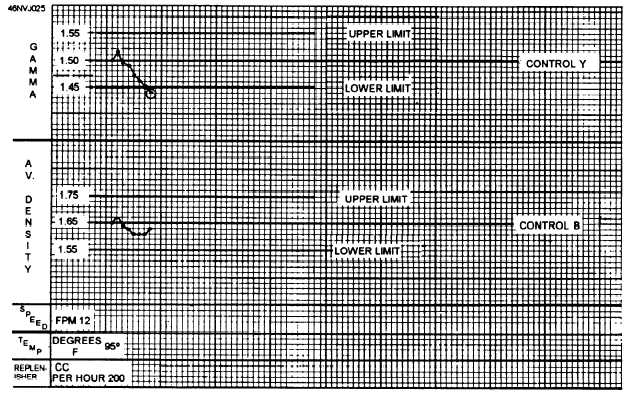

If, for example, the control gamma in an aerial

film processor is 1.50 and the desired average density

is 1.65, you must have a method for indicating when

the gamma or varies to the point where the end

result is no longer desirable. When the gamma

tolerance limit is ±0.05 and the tolerance limit

is ±0.07, the control chart appears as shown in figure

2-12.

Figure 2-12.—Control chart.

2-23