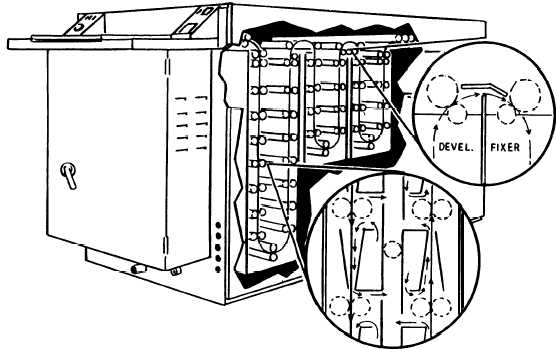

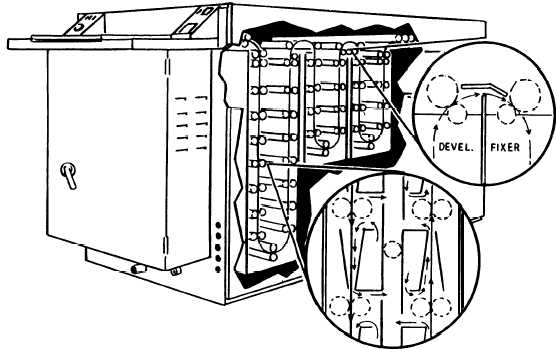

Figure 10-21.–Roller transport processor.

operation, and maintenance instructions supplied with

it. Therefore, in this section only general information

that applies basically to any machine processor is

discussed.

TRANSPORT SPEED

Most black-and-white automatic film processors

have a variable speed operation. Unlike hand processing

where developing time is measured in minutes and

seconds, machine processing developing times are

measured in feet-per-minute (fpm). Both methods

measure the length of time the material is affected by

the developer and other solutions. Most color processors

have a set machine speed that can only be adjusted

slightly because color materials must be processed to

specific parameters so processing cannot be manipu-

lated.

The time the solutions are allowed to act on the film

or paper is a result of the speed that the machine moves

the sensitized material and the length of time the

material is immersed in a particular tank. Most machines

have an fpm indicator that shows the set speed of the

processor. The temperatures of solutions and the

specific number of feet in each section of the machine

are usually constant factors. It is the rate the paper or

film travels that determines the total processing time; for

example, if the speed is set to 10 fpm and the total roller

path in the developing tank is 30 feet, a certain point on

the material being developed takes 3 minutes (30

10).

Regardless of the machine speed, film or paper

cannot be processed faster than the total required

solution times. For example, you are processing film

that requires a processing and drying time of 10 minutes

and 20 seconds. When the machine is processing this

film, it takes 10 minutes and 20 seconds before the first

foot of film leaves the dryer. However, the total time to

process the entire roll is related to the speed of the

machine and the total length of the material. For

example, if the machine speed is 10 fpm and the roll is

10 feet long, the film takes 10 minutes, 20 seconds, plus

1 minute (10

10). With a 200-foot roll, access time is

10 minutes, plus 20 seconds, plus 20 minutes

(200

10), or a total of 30 minutes, 20 seconds. It is

important for you to know the access time of the

processor. When the material being processed does not

exit the machine in the required time, a machine

malfunction or jam is evident.

WATER TEMPERATURE AND FLOW RATE

Wash water is an important processing con-

sideration. Not only is the water temperature important

but also the flow rate of the water. Two factors that must

be considered are as follows: sufficient flow to ensure

10-29