Whenever a problem is suspected.

As soon as a control strip comes out of the dryer,

identify it with the time and date of processing (not

the time it was actually read). A code number

identifying a machine or operator is also helpful when

your facility has more than one of the same type of

processor.

Always inspect a control strip for physical or

chemical defects before reading the appropriate

densities. Use the middle area of the density steps for

taking the density readings. Make each measurement

twice. You should use a slightly different area of the

step each time, and average the readings.

The emphasis in process monitoring is on

densitometry. Keep in mind, however, that changes in

the process are made by chemical and mechanical

variations, intentional or not. Problems are much

easier to track when records are kept of all intentional

changes in the following:

Machine speed

Solution temperatures

Replenishment rates

Agitation

Filters

Squeegee adjustments

Parts (racks, gears, pumps, and lines)

Operators

Processing solutions

Types of film

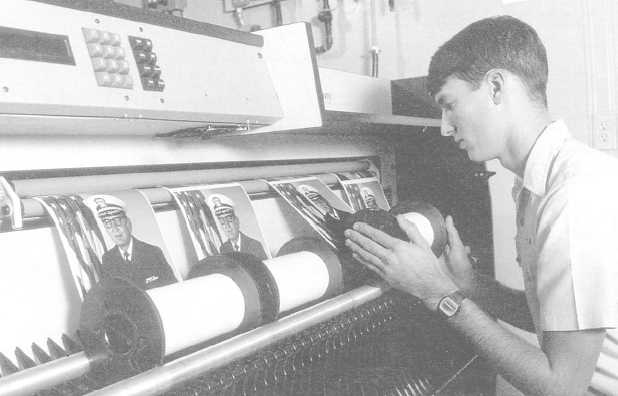

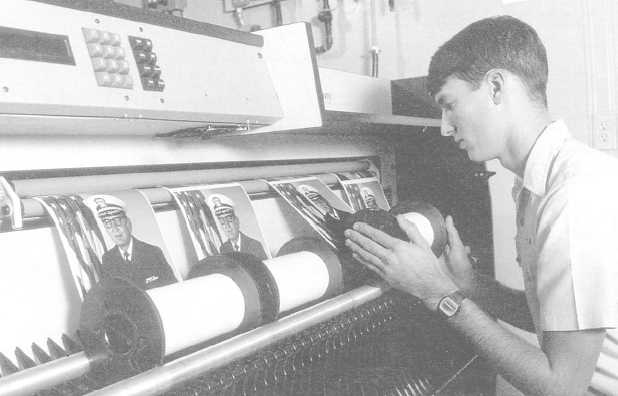

Figure 2-19.—A Navy Photographer’s Mate inspects prints for physical defects that are exiting a processor.

Photo by PH2 Sharon Nelms-Thorsvik

2-36